Ford recognise the expertise and capability they have in the UK says Director, Julian Hetherington

The Advanced Propulsion Centre is delighted that Ford is building on its commitment to UK-based innovation, after announcing today (Monday 18 October 2021) its e-Drive production plant will be based in Halewood, Merseyside.

The decision comes following Ford’s successful bid for funding through the APC managed Automotive Transformation Fund, but is seeded in a number of earlier collaborative low-carbon research and development projects, as Julian Hetherington APC Automotive Transformation Director, explains:

We are delighted that Ford has made this commitment to the UK and the Halewood site. We know that the insight and capability gained from various APC-supported projects, together with the ATF investment funding from Government to support the transition of its operations, put the Halewood site in a really strong position. It is a great example of the importance of continuing to invest in collaborative research and development, as having that engineering expertise in the UK makes a stronger case for siting the manufacturing activity here and accelerates the UK’s progress towards net zero.

The Ford Halewood site currently produce transmissions for internal combustion engines. ATF funding will support the transition of operations there and use and enhance existing skills of the workforce to manufacture electric drive units (EDUs). EDUs, in simple terms, control all the elements that move the wheels on an electric vehicle, including the speed, torque and direction.

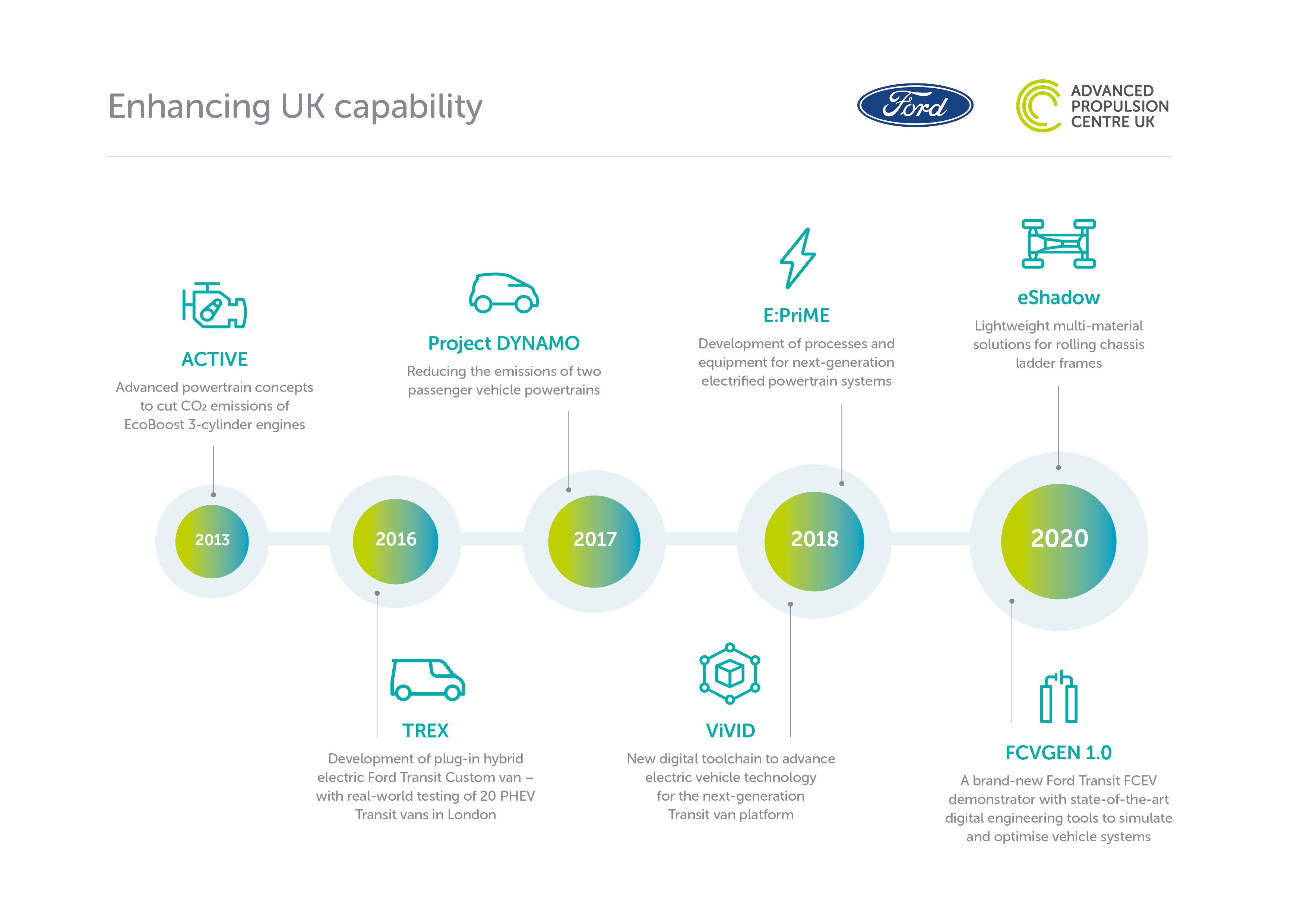

One of APC’s very first funded projects back in 2013 was with Ford, on developments that significantly cut the CO2 emissions on the incredibly successful EcoBoost engine. Since then there have been a total of seven collaborative R&D projects, working closely with Ford’s UK technical centre at the Ford Britain Dunton Campus in Essex. Two projects in particular – ViVID and E:PriME – played a major part in today’s announcement.

E:PriME enabled Ford to develop a pilot facility for e-Drives, creating the capability and processes for the high-volume manufacturing of next-generation low-emission technology that will be in operation in Halewood.

However, the benefits will not just be felt by Ford, as Julian goes on to explain:

Our insight has identified more than £24 billion of opportunity in the UK for the EV passenger car market alone and £12 billion of this is in power electronics and electric machines. So, while this is excellent news for the teams we have worked with across Ford UK, it will also benefit the supporting UK supply chain for electronic drive units and could potentially lead to more jobs in British businesses supplying the Halewood site. I’m especially pleased that the plant, part of the wider Ford Halewood estate where I started my career as an engineering graduate 34-years-ago, is going to provide the same great career opportunities for the next generation and in green technologies that will truly be transformative in achieving our net zero ambition.